【ベストコレクション】 s&op process cycle 188636

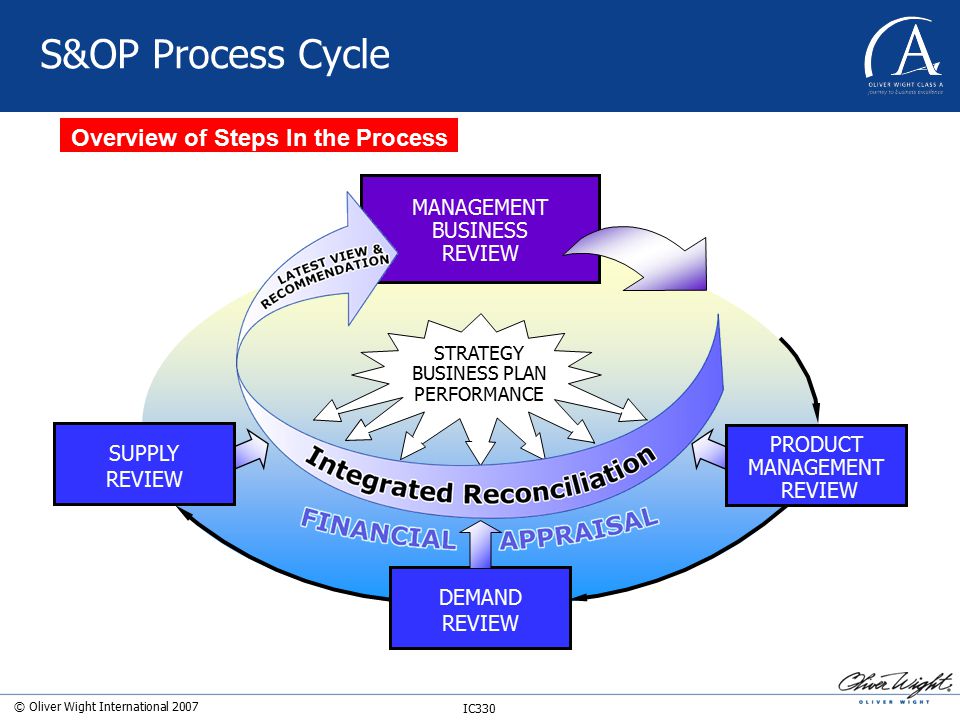

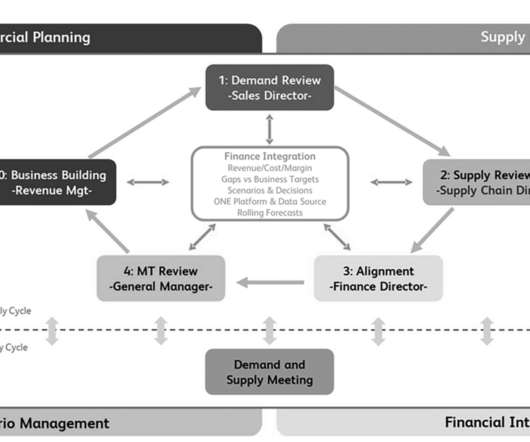

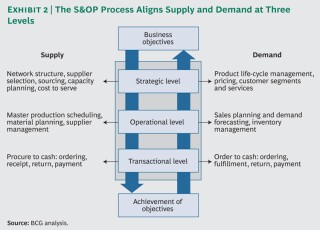

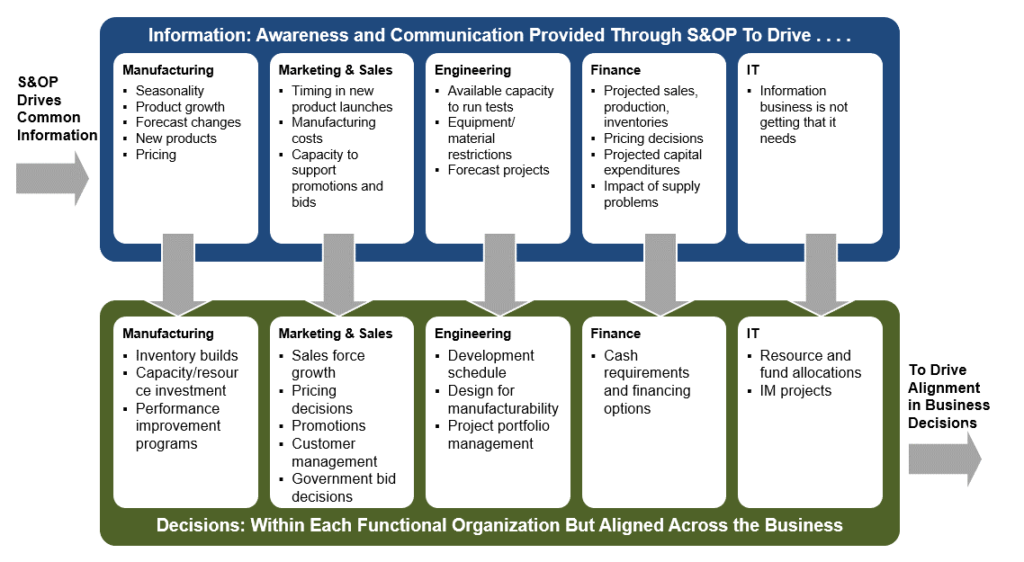

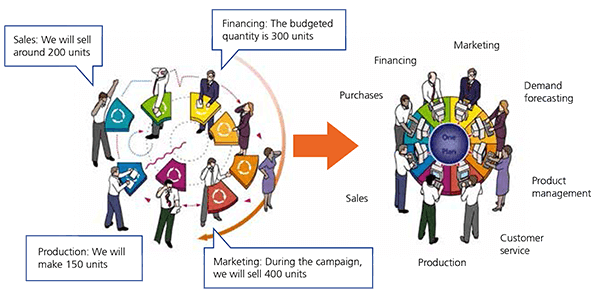

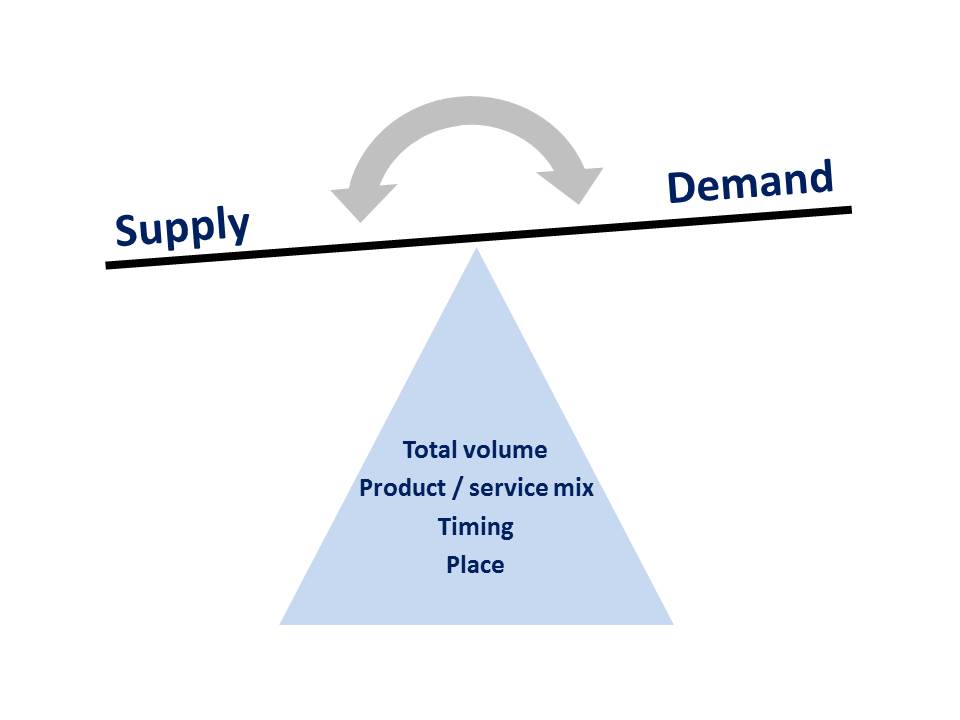

S&OP is a structured planning process, based on a monthly cycle The objective is to improve the balance between future demands for the market's products and services, the organisation's resources and the supply of materials and services And, of course how the plan will be financed Implementing the S&OP process The same is true for supply chain planning Sales and operations planning (S&OP) focuses on a tactical horizon from 324 months and has completely different objectives than sales and operations execution (S&OE), which covers the near termS&OP is gaining attention among organizations eager to implement powerful tactical management processes to help them succeed while navigating a rapidly changing business landscape Short for Sales and Operations Planning, S&OP is an integrated business management process that aligns all facets of an organization to their key market goals, synchronizing them and allowing the

A Common S Op Process For Your Business Helps Planning Learn About Logistics

S&op process cycle

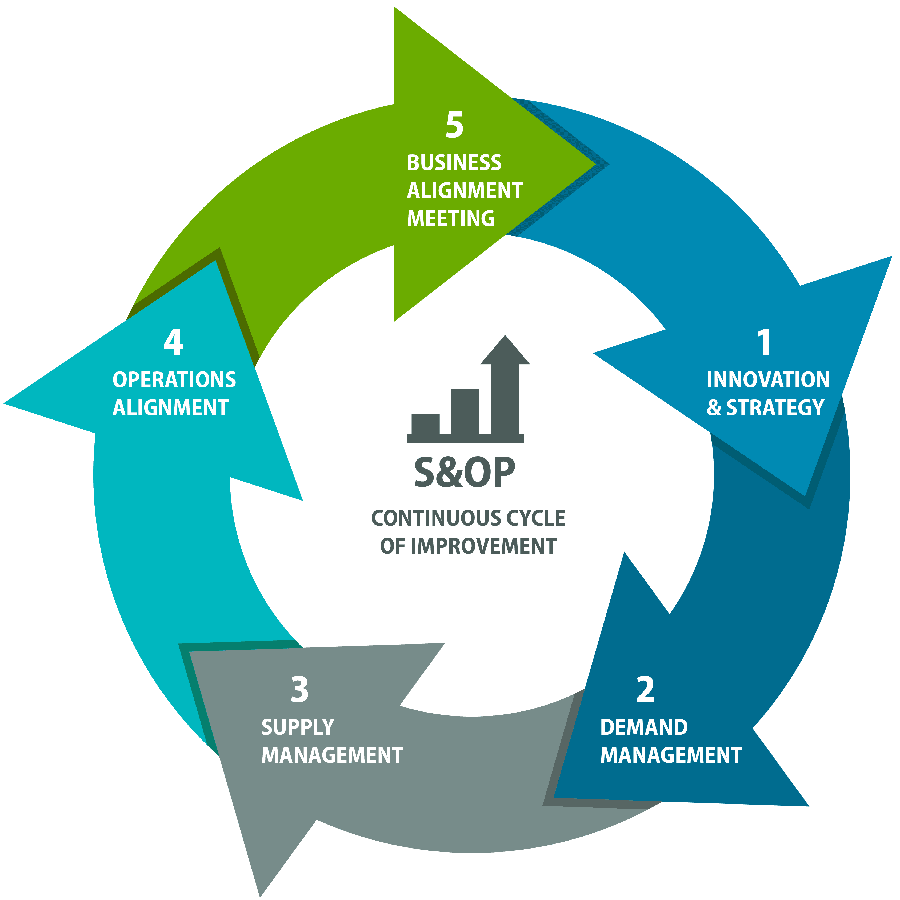

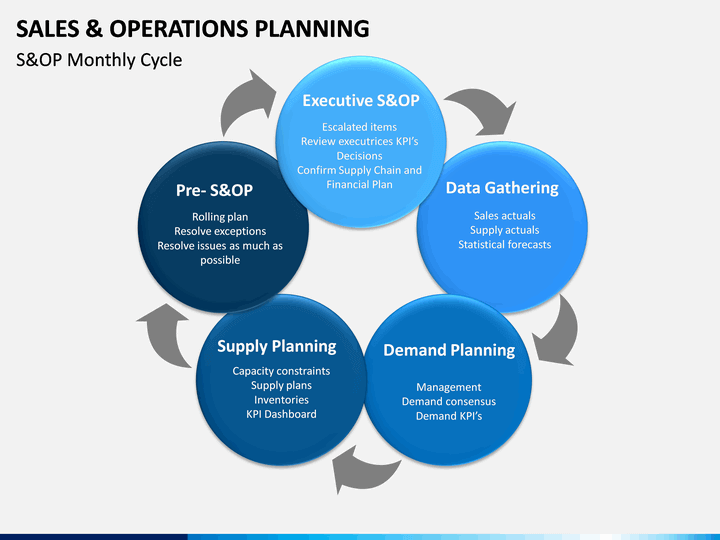

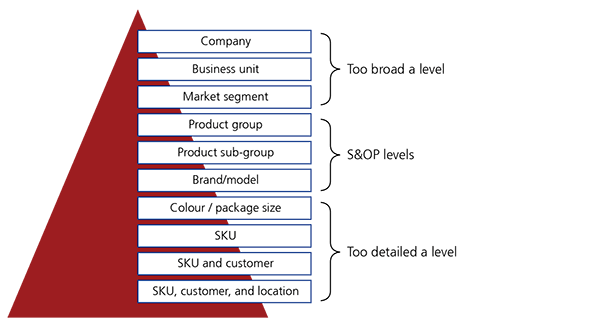

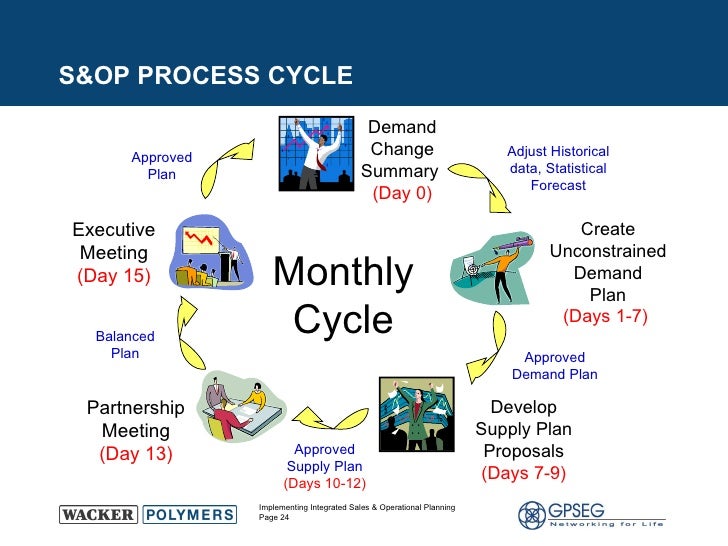

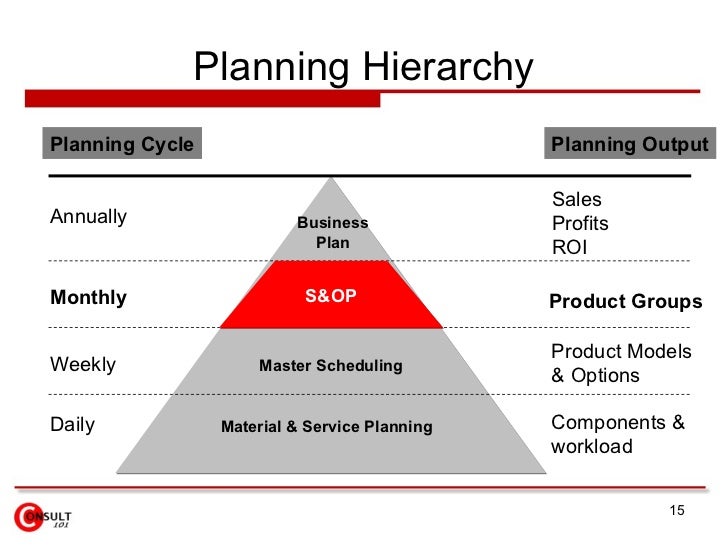

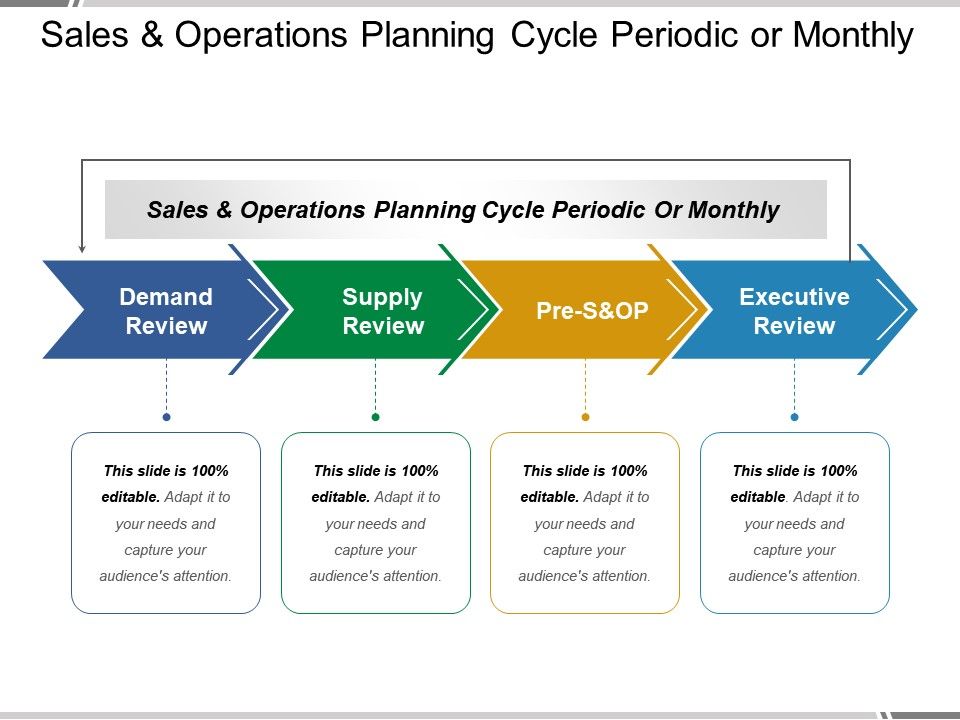

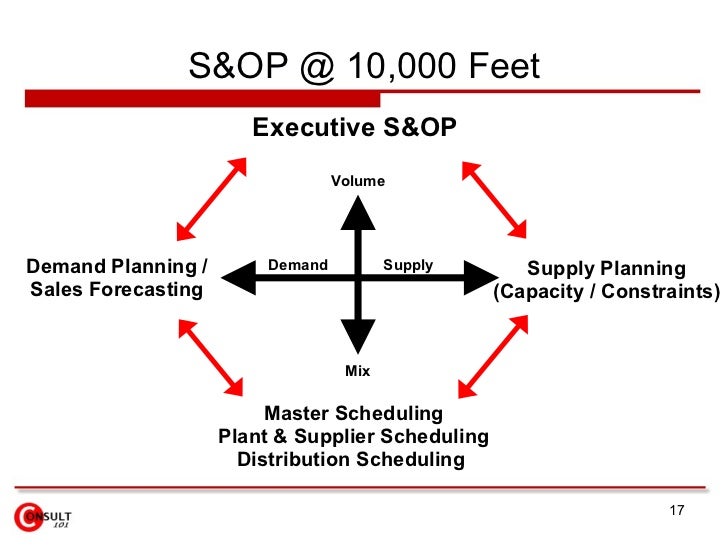

S&op process cycle- S&OP is a monthly management process that ensures that the company is focused, aligned, and engaged in those efforts the management team collectively decides are the priorities of the enterprise S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change The Executive S&OP planning cycle is monthly, with provisions for midperiod revisions when major changes occur Executive S&OP is an aggregate planning tool It focuses on aggregate volumes, and only rarely looks at issues of mix, ie individual products, stock keeping units, customer orders and so on

The S Op Cycle With Different Meetings đorđevic 17 P 44 Download Scientific Diagram

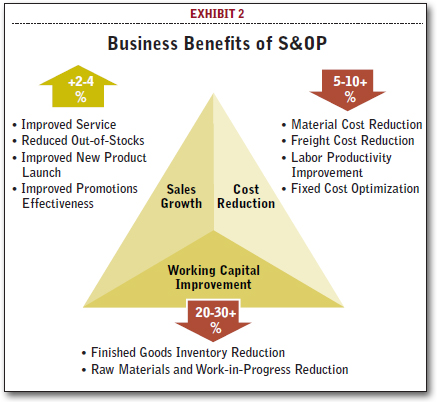

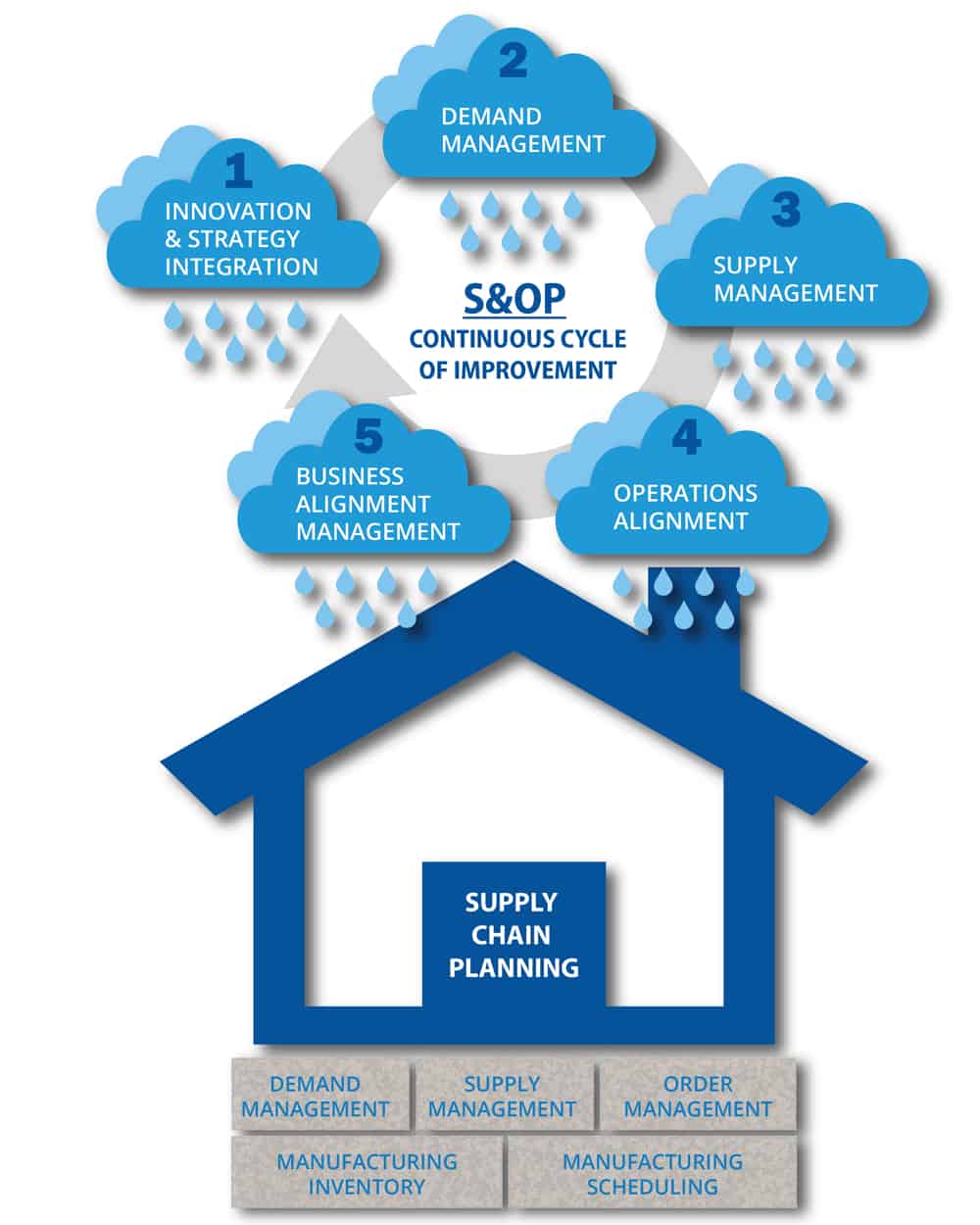

A robust S&OP process is the building block upon which to add inventory optimization and create an integrated SI&OP process The company that extends its capability beyond S&OP to SI&OP will reap the benefits of lowered working capital investment, improved service levels and increased salesIt is not an inventory replenishment tool!Process, must engage the general manager and direct reports Otherwise, there will be a disconnect between there wishes and the information on the formal SIOP document SIOP is not a scheduling tool!

Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are conduct 1Be familiar with the S&OP process and terminology used in OMP be able to navigate through the components of typical S&OP dashboards understand the S&OP functionality and be able to perform the actions carried out during the cycle Since the S&OP process is a key component of effective supplychain management, getting it right can be an important source of competitive advantage, especially in today's global markets A powerful lever for improving customer service, reducing working capital, cutting costs, minimizing risk, and shortening response times, effective S&OP

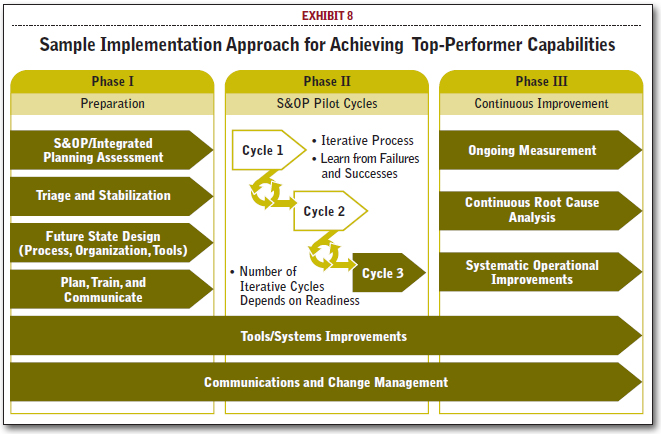

With a trusted S&OP process and leadership commitment lead to effective S&OP Because S&OP is a continuous process and reliant on new information, it improves from actual practice even at the risk of temporarily unfavorable outcomes TIP Identify optimal planning horizons by department and consider each department's planning needs In general, S&OP Implementation Roadmap 1 S&OP Implementation Roadmap Implement S&OP, as a critical business process, championed by a crossfunctional team ofS&OP best practices share a common set of approaches Rely on a phased approach S&OP is much more an integrated set of business processes and technologies than a single, Develop an "outsidein" sequence of S&OP initiatives typically, the events that will have the most profound and Focus on

1

Software For Sales Operations Planning In Europe Supply Chain Movement

S&OP Challenges Challenges Senior leadership support & "walk the talk" Achieving process compliance Identifying S&OP Champion or expert to lead implementation Clear definition and acceptance of roles and responsibilities, including defining specific objectives in employee appraisals Establishing S&OP meetings as the business priority Adapting the process to theThe collaborative crossfunctional nature of the S&OP process lends well to supporting a new product launch, as well as visibility to any potential issues before they arise Make the New Product Development Part of the S&OPAccording to research, around 5070 percent of businesses have been struggling to reap its full benefit A poorly implemented S&OP process can trigger a vicious cycle in which existing failings in the process are exacerbated over time, leading to a

Going Global With Sales And Operations Planning Ppt Video Online Download

What Is S Op How S Op Works Demand Planning Com

S&OP is based on four pillars i Establish the S&OP function in the organizational structure • Neutral position between sales and production • Sponsorship / representation on a senior management level ii Design and implement S&OP processes • Do, Accountable, Consult, Inform matrix • Business processes / flow schemesIt is, however, a top level planning technique to provide overall rates of sales and production, andEmail Address Subscribe to Supply Chain Game Changer Featuring Our 10 Best Inventory Management Articles!

Retail And S Op Supply Chain Brief

Is Sales And Operations Planning A Digital Age Process Enterra Solutions

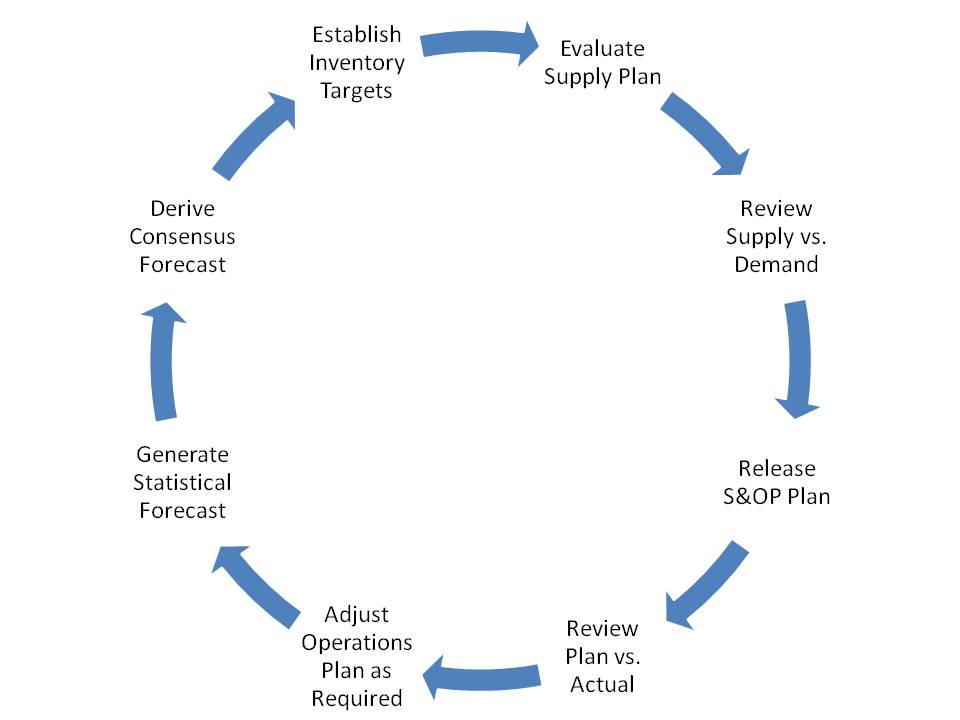

S&OP is an oldline methodology that has been thoroughly updated to work in today's datadriven, technologyfocused manufacturing world And when you add technology to productions systems, you get a mountain of data to comb through, looking for ways toAccording to IBF, S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply When establishing your process, it is important to consider who will be responsible for each step of the process You will also want to set expectations for handoffs, meetings, and how you will communicate changes Effective S&OPIt is an iterative process in which results from one planning cycle are compared with the next to provide management with trend information from across the business Participants evaluate timephased projections for supply and demand to ensure that the tactical plans in all business functions and geographies align and support the company's strategy

Sales And Operations Planning

S Op Five Steps To Get Started Supply Chain Shaman

The Objective of the S&OP Process The overall objective of the S&OP process is to agree on an aligned set of feasible functional plans and targets for the next 18 – 24 periods, consistent with Process A robust S&OP process description which is deployed with discipline and consistency Systems Providing effective and wellintegrated systems to facilitate execution of a regular monthly planning cycle The second step is to put in an alert mechanism that flags when the current S&OP process is out of date Most S&OP installations operate on a time cycle (monthly) and there is no mechanism in place to replan within a cycle This is like driving down the highway at a constant speed and ignoring all other vehicles

Supply Chain Graphic Of The Week The S Op Process

Achieve Excellence In Sales And Operations Planning Sapinsider

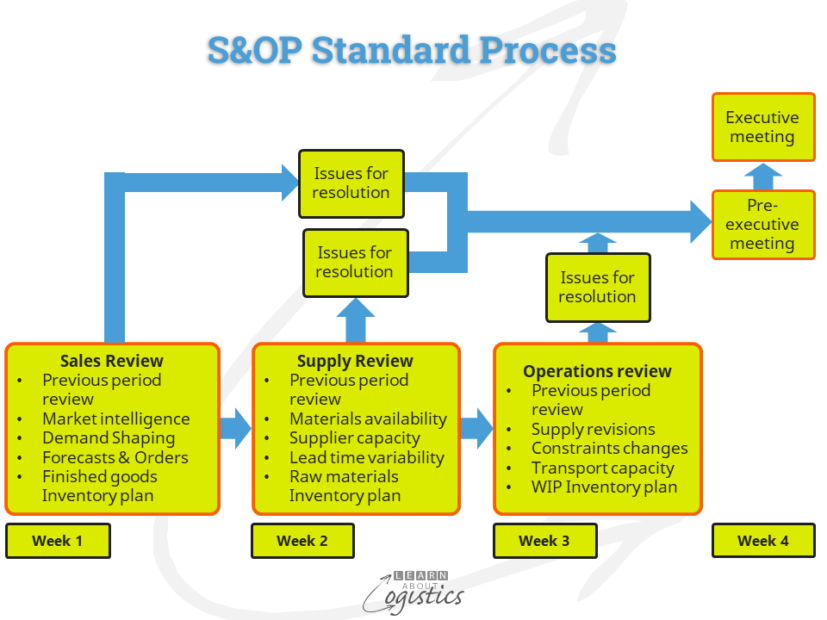

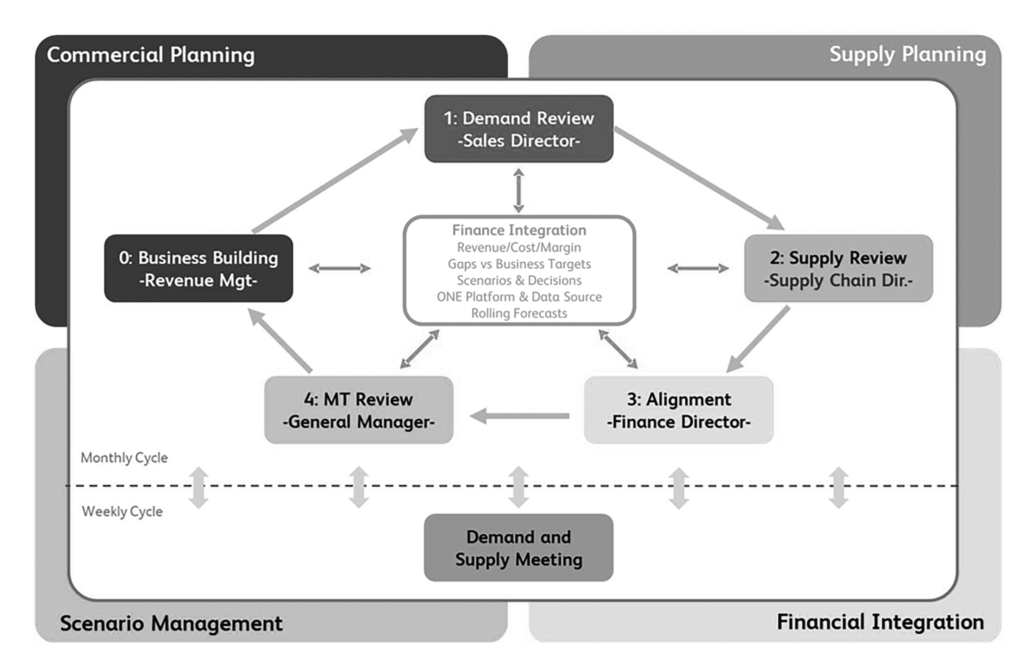

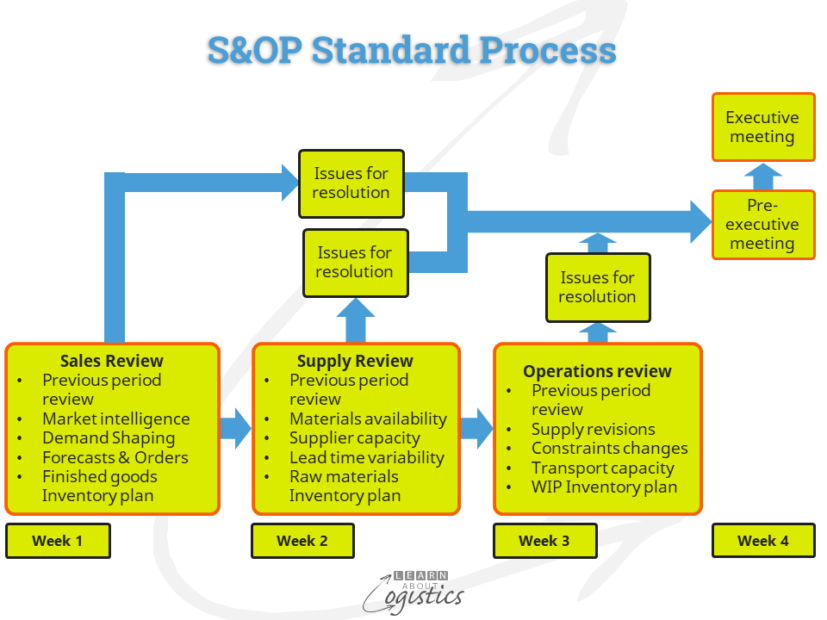

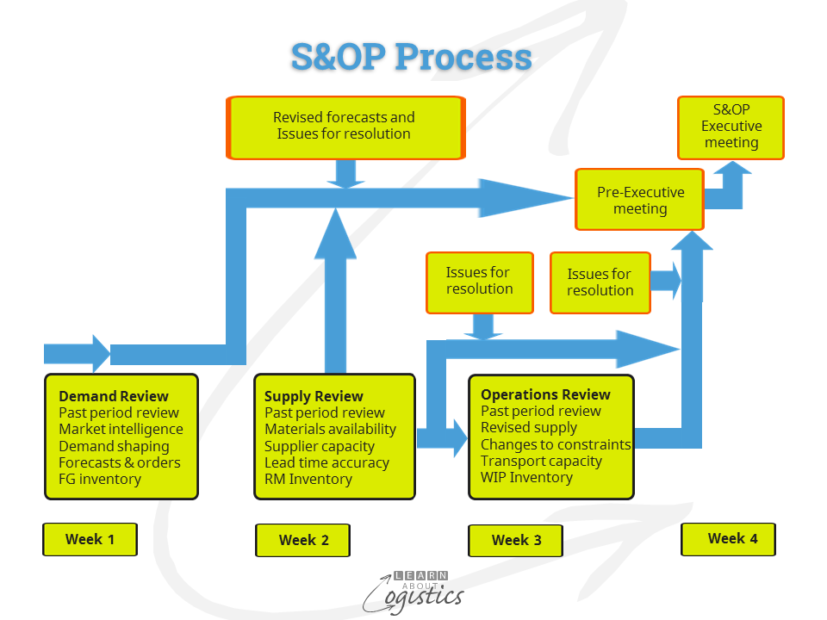

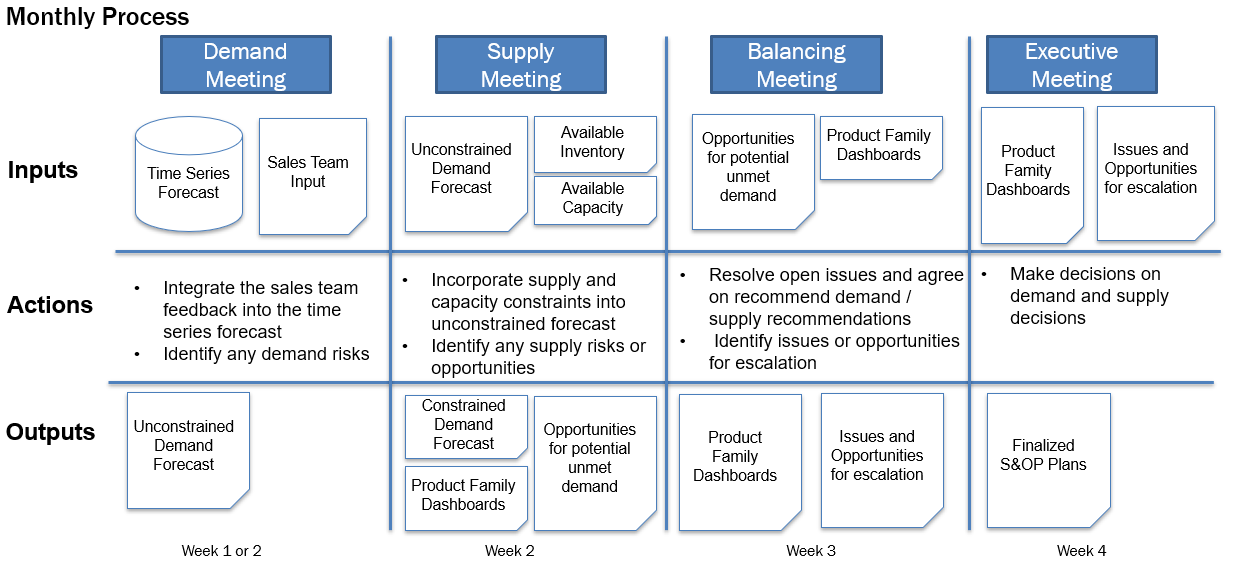

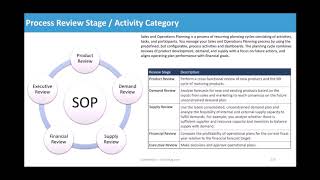

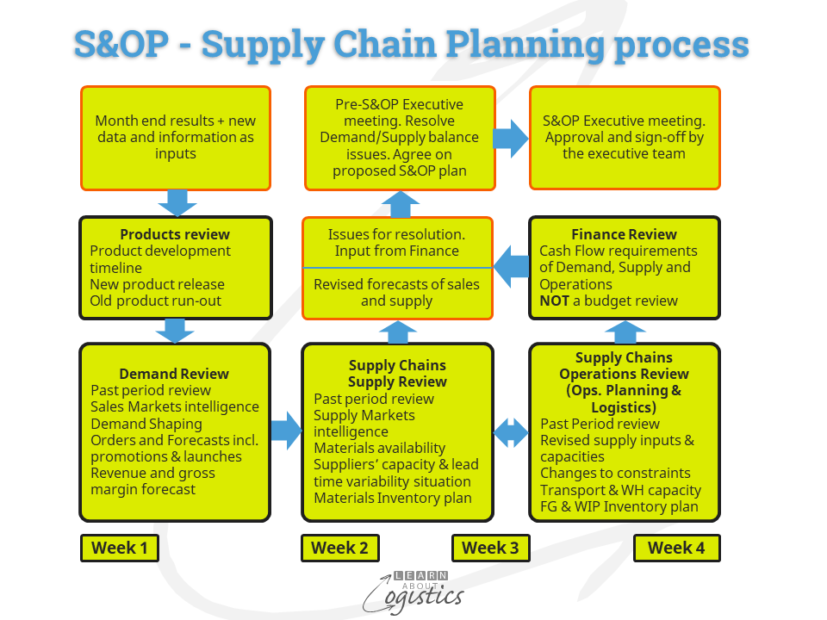

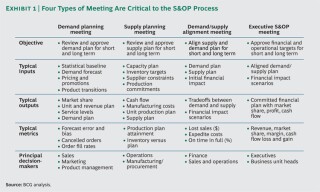

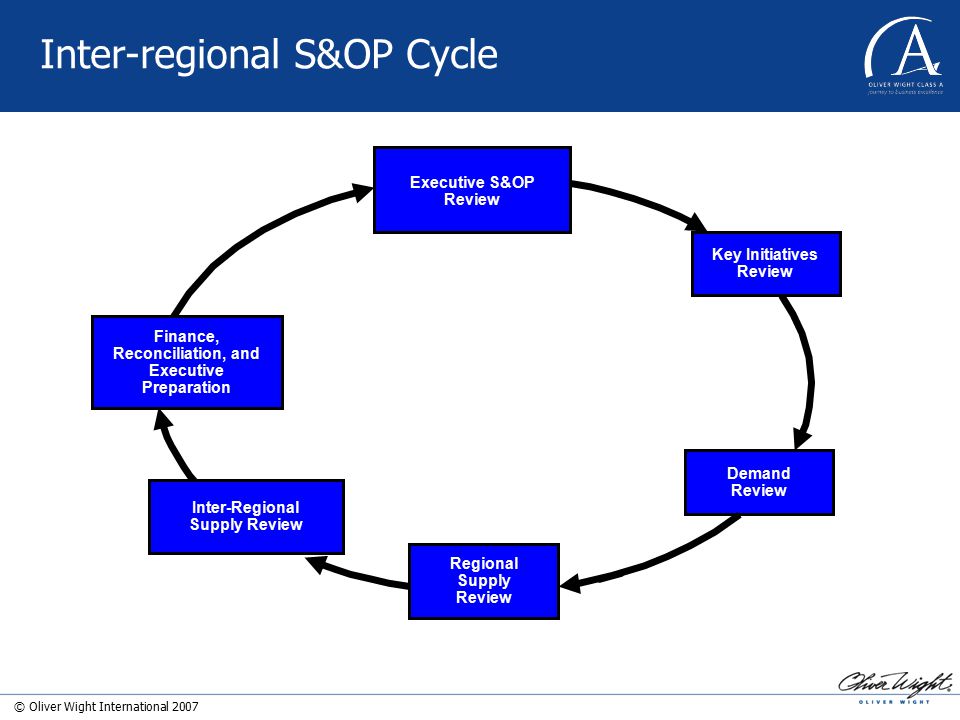

4 Challenges in Starting and Sustaining a SIOP (S&OP) Business Process! The S&OP process The process consists of focused review meetings for each discipline and an Executive meeting for decisions The diagram shows a standard model, but the actual number of review meetings are decided within each organisation For example Finance input is part of the preexecutive meetingAn S&OP process successful In Figure 1, there is a list of a dozen factors that can help lead to operating an S&OP process that maintains exceptional supply chain operational performance over time These factors are detailed below 1 Ongoing, Routine S&OP Meetings A key aspect of an S&OP process is that it is comprised of routine meetings

Sales And Operations Planning Cycle Chainsequence Inc

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

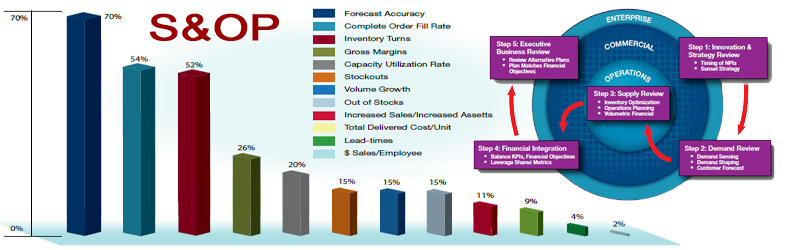

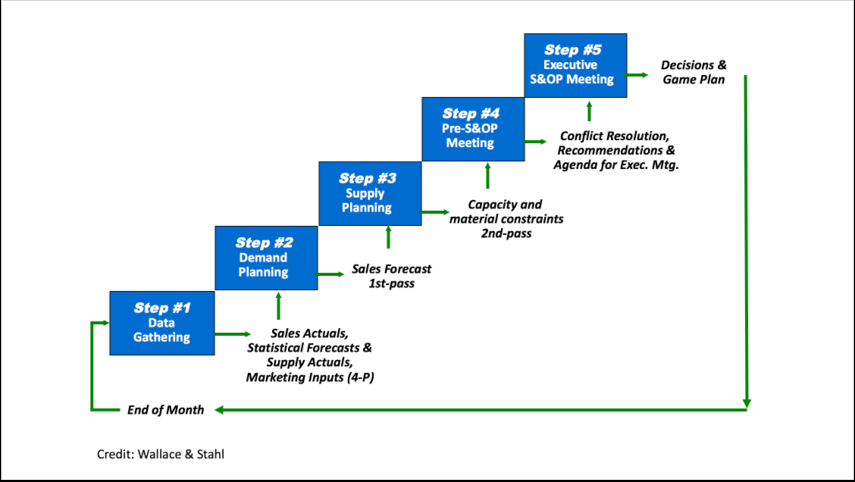

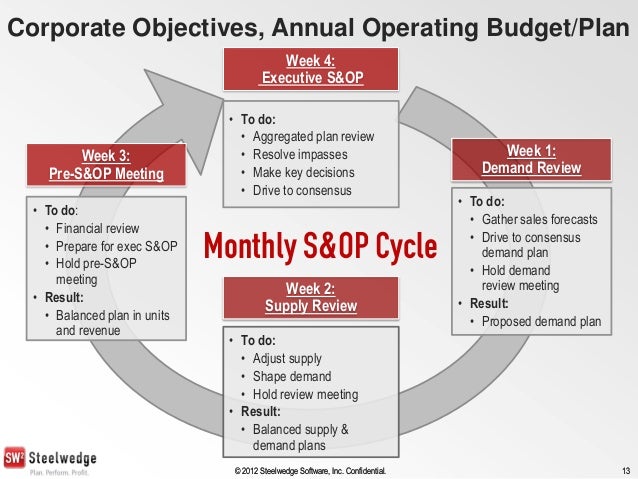

A company might follow one of a few slight variations of the stepbystep S&OP process The accompanying graphic shows a monthly fivestep process data gathering, demand plan, supply plan, preS&OP, and finally the executive S&OP meeting, where decisions are made Service levels – this metric will measure how well you satisfy your customers from ontime delivery, complete orders, etc This is sometimes measured by the "perfect order" Lead time – the shorter your lead times vs competition, the more likely you'll be able to grow sales, assuming all else is equal Margins – how well you have Goal of S&OP process Below figure shows a typical monthly cycle for sales and operations planning The demand review is performed first, followed by the supply review with possible supply chain constraints (for example, reduced capacity) before the sales and operations planning meeting is conducted

Optimise Your Sales And Operations Planning S Op Slimstock Uk

Sales And Operations Planning Myths Part 3 Supply Chain 24 7

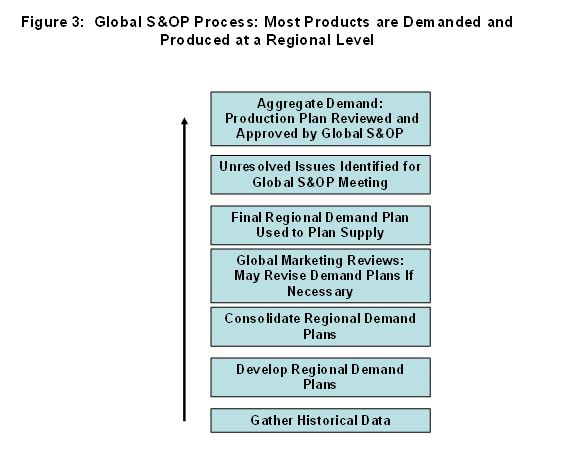

S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply Implementation of S&OP should be undertaken in phases Most businesses start with a pilot program in one business unit in one country, for exampleGet Our EBOOK HERE A Sales, Inventory and Operations Planning (SIOP) business process is an essential element for running a successful business S&OP although simple in concept is very difficult to implement well Check this list of the essentials during your next S&OP cycle and if you can tick all the boxes, you're doing a good job and can move on to adding more KPIs and reports that ensure your S&OP process is strongly aligned to your strategy

A Comprehensive Overview Of Sales And Operations Planning S Op

Oracle Demantra Sales And Operations Planning User Guide

Set Up Sales and Operations Execution Process to Support the S&OP Cycle Published 28 January 16 ID G Analyst(s) Marko Pukkila Summary S&OE is an oftenoverlooked process that keeps manufacturers' S&OP from reaching its full potential The S&OP process linkage to detailed planning began swiftly and continued to evolve whereby the process moved from a simple spreadsheet application to a contained solution This new broad management style allowed the management team to make the factbased decision more quickly and seamlessly and as a unified organizationWhat Is the Integrated Business Planning (Advanced S&OP) Course This course takes participants through each step of a best practice IBP process Participants learn how to make each review step in the monthly IBP cycle worthy of business leaders' time

Driving Supply Chain Agility With S Op And S Oe I Kinaxis

Pdf Sales And Operations Planning S Op An Overview

Common misconception that deploying S&OP (or more likely, its latterday incarnation, Integrated Business Planning), will fix these issues Integrated Business Planning is a powerful decisionmaking process that sits at the heart of the Oliver Wight Integrated Business Model (Figure 1) and is the Annual planning/budgeting focuses on business decisions with long lead times such as adding or removing capacity, developing new products or entering new markets Monthly S&OP focuses on planning at the product family level Weekly S&OE focuses on the SKU level, tracking how demand and supply match the plan Establish an S&OE process that supports the S&OP cycle This usually doesn't require starting from scratch Examine your current S&OP cycle and identify all the activities that should fall under the S&OE umbrella Any activities dedicated to the next zero to three months should immediately be moved to S&OE

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

S&OP Integration with other Plans Source Adapted from "Operations ManagementProcesses and Value Chains", Krajewiski et al, 08, PHIL P Ltd, Milliken (07) and Lapide (04) identify S&OP as The demand consensus meeting is one of the most important steps in sales and operations planning (S&OP), with the resultant demand plan serving as a critical input for all other S&OP process meetings Without a demand plan as a The reasons are plenty, but one of the core reasons is the lack of senior leadership support Another reason is that employees just get tired of an overly dogmatic, bureaucratic process and data focused monthly cycle Maybe at the start of the S&OP project executives buy in and employees are still eager Usually lead and motivated by supply

Sales And Operations Planning S Op Logistiikan Maailma

Sales And Operations Planning Powerpoint Template Sketchbubble

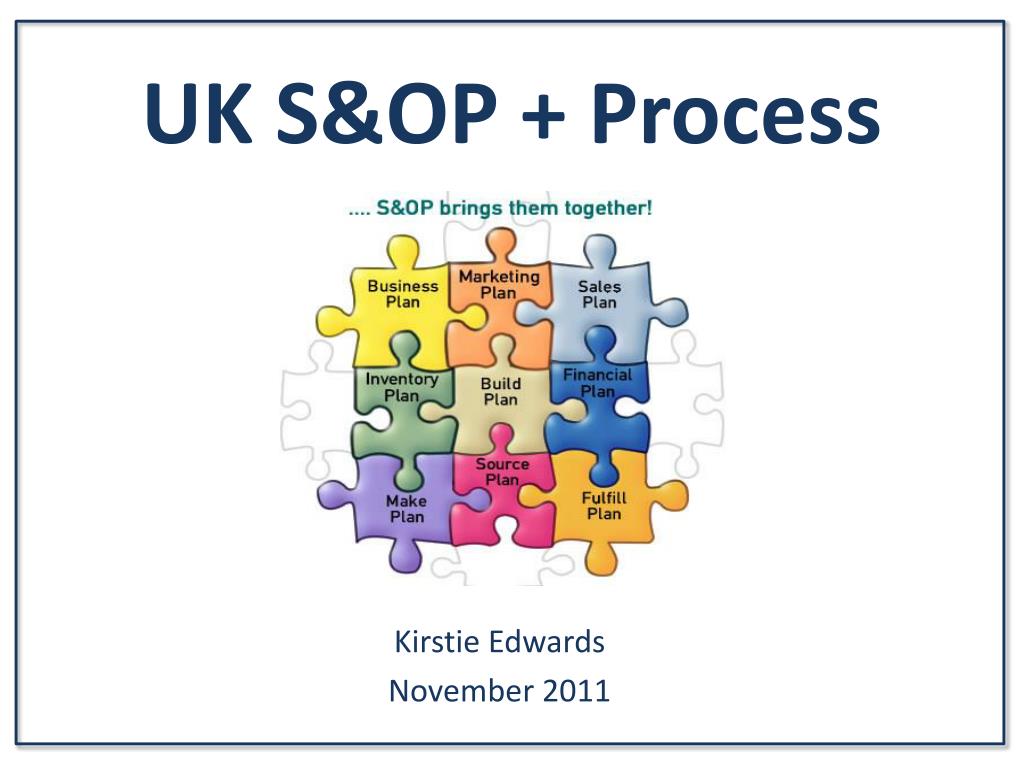

The process brings together all the plans for the business (sales, marketing, development, manufacturing, sourcing, and financial) into one integrated set of plans APICS Dictionary, 14th edition S&OP Processes Planning Objectives of S&OP ‐ S&OP supports and measures the progress of the entire organization in meeting the

Tackling Life S Big Questions What Is S Op

Gartner Blog Network

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Integrating The S Op Process Go With The Flow Business 2 Community

1

Aktuelles Von Aca Solutions Sales And Operations Planning To Industrialize The Aerospace Supply Chain

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

What Is S Op How S Op Works Demand Planning Com

A Common S Op Process For Your Business Helps Planning Learn About Logistics

The S Op Cycle With Different Meetings đorđevic 17 P 44 Download Scientific Diagram

What Is One Plan S Op Arkieva

A Comprehensive Overview Of Sales And Operations Planning S Op

Sales And Operations Planning Relex Solutions

One Sales And Operations Planning Process Guide Cycle Powerpoint Slides Powerpoint Presentation Slides Ppt Slides Graphics Sample Ppt Files Template Slide

Monthly S Op Process Sales And Operations Planning Wikipedia Sales And Operations Planning Best Apps For Teachers Apps For Teachers

Product Lifecycle Management S Op Slimstock Uk

Implement The S Op Process For Supply Chain Success Learn About Logistics

Executive S Op Case Study Presented At Gpseg

Who Should Own Sales And Operations Planning I Kinaxis

Sales Operations Planning Consulting Supply Velocity

Getting To Grips With Sales And Operational Planning Bloor Research

Ppt Uk S Op Process Powerpoint Presentation Free Download Id

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Sales Operations Execution S Oe Vs S Op Toolsgroup

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

1

Oracle Cloud Applications Supply Chain Planning Intro To Sales And Operations Planning Youtube

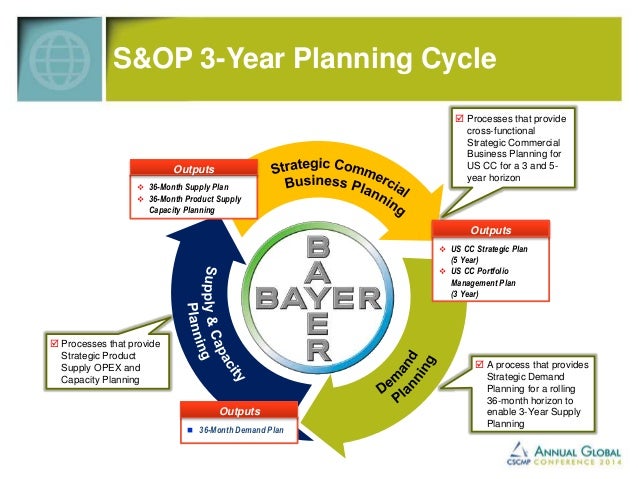

Cscmp 14 Bayer Putting The S Back In S Op

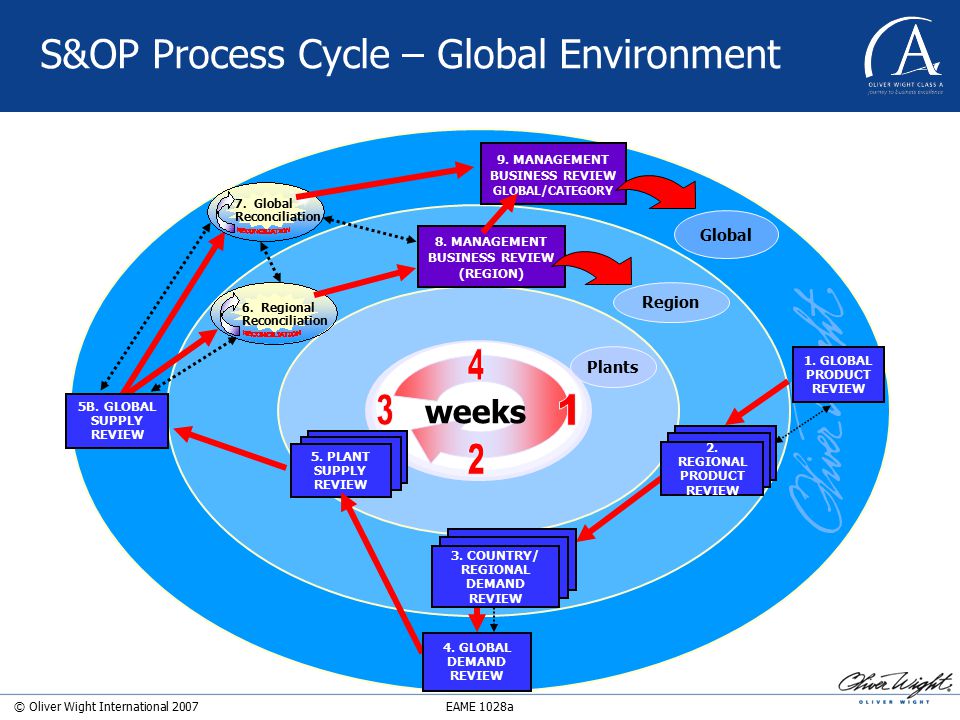

Going Global With Sales And Operations Planning Ppt Video Online Download

Successful Sales And Operations Planning In 5 Steps

What Are The Basic Elements Of The S Op Process Quora

Sales Operations Planning Scpi

Sales And Operations Planning Report Do You Get Surprises

S Op Five Steps To Get Started Supply Chain Shaman

Achieve Excellence In Sales And Operations Planning Sapinsider

Achieve Excellence In Sales And Operations Planning Sapinsider

Smoother Execution Through S Op Supply Chain Management Review

S Op Is The Hub Of Supply Chains In Your Business Learn About Logistics

S Op And S Oe A Symbiotic Relationship

S Op Process

Sales And Operations Planning

Is Your Business Suffering From S Op Churn Optimity Anz

How S Op Improves Your Organization Tmc Fr

What Is S Op How S Op Works Demand Planning Com

Sales And Operations Planning S Op 101 Smartsheet

Sales And Operations Planning Relex Solutions

S Op Five Steps To Get Started Supply Chain Shaman

What Is S Op Sales And Operations Planning Explained Anaplan

Achieve Excellence In Sales And Operations Planning Sapinsider

Scielo Brasil Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa De Material De Escrita Um Estudo De Caso Avaliacao Da Maturidade Do Processo De S Amp Op Em Uma Empresa

Sales And Operations Planning Cycle Periodic Or Monthly Powerpoint Presentation Sample Example Of Ppt Presentation Presentation Background

What Is S Op How S Op Works Demand Planning Com

Sales And Operations Planning Anaplan Community

2

Smoother Execution Through S Op Supply Chain Management Review

1

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

What Are The Basic Elements Of The S Op Process Quora

Good Sales And Operations Planning Is No Longer Good Enough Bain Company

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

S Op In Las Vegas Let S Learn Laugh And Be Entertained At The S Op Innovation Summit

What Is Sales And Operations Planning S Op Plex Demandcaster

Sales And Operations Planning Relex Solutions

Going Global With Sales And Operations Planning Ppt Video Online Download

Example Of The Monthly S Op Calendar Of The Company Studied Source Download Scientific Diagram

S Op Planning Services Chainsequence Inc

Sales And Operations Planning Process Self Assessment

2

S Op Five Steps To Get Started Supply Chain Shaman

2

S Op Introduction

What Is S Op Sales And Operations Planning Explained Anaplan

Sales Inventory Operations Planning Si Op A Roadmap To Si Op Success Pragmatek Consulting

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

S Op Process

Sales And Operations Planning S Op Logistiikan Maailma

S Op Process Impacts Excess Finished Goods And Operational Efficiency Hawkeyeconsultingadvisors

What Is S Op Sales And Operations Planning Sap Insights

Improving Profitability With Sales Operations Planning Magellan Consulting Group

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

コメント

コメントを投稿